Cronimet Specialty Metals is a manufacturer of CARBIGRIT™, crushed tungsten carbide and tungsten carbide grit for hard-face applications on new and used wear parts such as cutting edge blades, bucket teeth, trencher teeth and other heavy construction equipment.

Get an extra layer of protection, increase efficiency and decrease your downtime with our CARBIGRIT™, tungsten carbide grit wear resistant solutions.

Our CARBIGRIT ™, tungsten carbide grit wear resistant solutions provide long lasting wear protection in aggressive wear applications. Through a process called hardfacing, an overlay of tungsten grit is applied to a base metal. The mesh distribution can be customized to achieve the desired balance of protection from abrasion and impact. Our high quality crushed carbide is preferred over traditional hardfacing materials because of its superior wear resistant properties. It is time-tested and proven to be the most effective solution to reduce product wear.

Benefits of CARBIGRIT™, Tungsten Carbide Grit

Industries utilizing our CARBIGRIT™ tungsten carbide grit wear resistant solutions

Wear parts are costly and enhancing their protection through the application of our CARBIGRIT™ crushed carbide extends the life of your wear part, helps reduce downtime and increases production efficiency. Particular pieces of equipment and wear parts that are enhanced in terms of abrasion and/or impact resistance include tillers, rippers, sweeps, loaders, graders, milling attachments, shredders, stump grinders, debarkers, drill collars, drill pipe and tubulars. Companies in industries benefiting from the use of our CARBIGRIT™ crushed carbide wear resistant solutions include: earthworks, wood & stone, agricultural, drilling & trenching, forestry, oil & gas, mining & construction.

Our CARBIGRIT™ is custom made to meet the needs of our clients’ applications and packaged in a safe and secure supply chain.

Certificates of Analysis

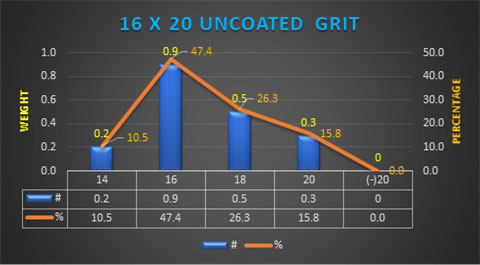

We provide certificates of analysis showing your tungsten carbide grit’s particle size distribution.